This case originates from a case that the author has tried. The claims in

this case are very special. There is only one claim, and it is very simple. The

request is successful and invalid. From the perspective of the use of invalid

evidence in this case, the author is willing to do some discussion.

Brief introduction to the case

The claims in this case are as follows:

1. Ball mill stepped cylindrical lining plate, it is characterized in that:

described ball mill stepped cylindrical lining plate, the wave crest of the

lining plate is stepped, and a wave crest is made up of at least two steps; The

height of the described steps is all greater than the small diameter The radius

of the grinding ball is smaller than that of the large-diameter grinding ball;

the width of the steps is larger than the radius of the small-diameter grinding

ball.

This case belongs to the field of ball mills. Usually, a certain number of

solid spheres and materials to be crushed are placed in the cylindrical drum of

the ball mill. The material is crushed to the required particle size. The

invention of this patent is that the inner wall of the drum has a stepped lining

plate, and the solid sphere is divided into a large ball and a small ball. The

purpose of such a design is that the small balls can occupy a considerable part

of the surface area of the drum. When the drum rotates, the large balls are

lifted and rolled down and can land on the small balls on the steps, thereby

reducing the protruding effect of the liner. The wear of the wave crest extends

the service life of the liner.

Invalid the first time

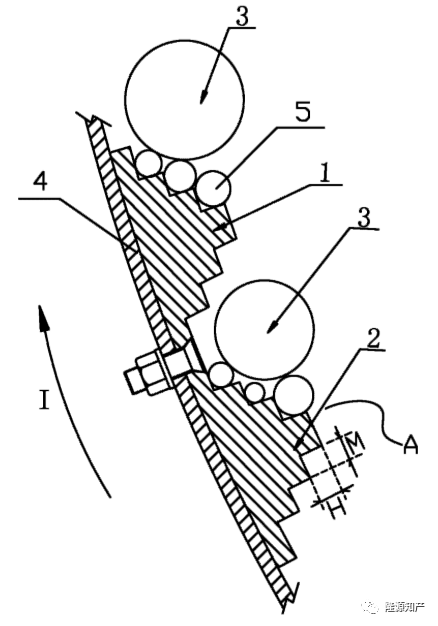

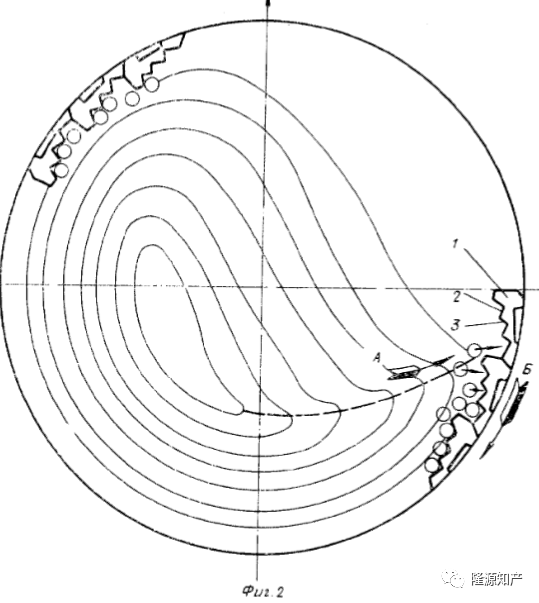

In the first invalidation, the petitioner used a patent of the former Soviet

Union as evidence 1. As shown in the figure, the barrel of the ball mill in

evidence 1 has a stepped lining plate, and the grinding balls are stuck when the

barrel rotates. On the steps, it can be brought to a higher position and then

thrown away, and the grinding balls will not accumulate at the upper position of

the bottom, thereby increasing the effective volume of the ball mill and

improving the productivity, and the wear conditions of each step are the same,

keeping the shape and performance of the lining. However, evidence 1 does not

disclose that the ball mill has two kinds of grinding balls of large and small

diameters, so it also does not have most of the large-diameter grinding balls in

this patent and can only contact the small-diameter grinding balls and isolate

them from the wave crest, roll along the top angle of the step, and change the

sliding friction. For rolling friction, the large diameter grinding ball cannot

touch the side of the step, and it is difficult to contact the technical effect

of the top surface.

The evidence 2 used by the petitioner is the published textbook "Tube Mill",

which records that the grinding ball has an "average radius", but the average

radius only indicates that the radius of the grinding ball is different, but it

cannot be determined that the ball mill has obvious There is no evidence to show

that the distinction between large-diameter and small-diameter grinding balls is

common knowledge in the field, so there will be no large-diameter and

small-diameter grinding balls that fit with the steps, and the small-diameter

grinding balls stay at the surface as the cylinder rolls and rises. In the

convex edge, the large-diameter grinding ball and the small-diameter grinding

ball form rolling friction, which prevents the large-diameter grinding ball from

contacting the top surface of the step, thereby reducing the technical effect of

step wear.

Evidence 1 in the first invalidation is still relatively close to the idea in

this patent, but the technical feature of large and small grinding balls is not

disclosed, so the technical effect claimed in this patent cannot be

obtained.

Invalid second time

In the second invalidation, the petitioner submitted the following

evidence:

Evidence 1: Cover and pages 42-43 of the book "Grinding Machine Liner"

published by China Mineral Processing Technology Information Network in July

1985;

Evidence 2: British patent document with publication date of December 3, 1975

and publication number GB1416110A;

Evidence 3: The article titled "Discussion on the Influence of Ball Mill

Cylinder Liner Shape on Grinding Productivity" published in the journal "Copper

Engineering", 2001-04;

Evidence 4: The Chinese utility model patent with the authorization

announcement date of January 30, 2008 and the authorization announcement number

CN201012930Y;

Evidence 5: The Chinese utility model patent with the authorization

announcement date of November 8, 2000 and the authorization announcement number

CN2404586Y;

Evidence 6: The article titled "Optimum grading and ball-filling parameters

of steel balls in a steel ball mill" published in the journal "Journal of

Changsha University of Science and Technology (Natural Science Edition)", Volume

4, Issue 1, March 2007;

Evidence 7: The publication date of the Chinese invention patent application

published on April 16, 2008 and the publication number is CN101161347A;

Evidence 8: The Chinese invention patent with the authorization announcement

date of September 23, 2009 and the authorization announcement number

CN100542797C;

Evidence 9: An article titled "Experimental Research and Mechanism Analysis

of Mill Grading Liner" published in the journal "Cement", No. 4, 1994;

Evidence 10: The Chinese utility model patent with the authorization

announcement date of November 10, 1993 and the authorization announcement number

CN2145675Y.

Evidence 11: Chinese translations of British patent documents with

publication date of November 15, 1950 and publication number GB646012A and

relevant parts;

Evidence 12: The inner cover, copyright page, table of contents, back cover

and pages 277, 304, 343, 371 and A copy of the document reproduction

certificate;

Evidence 13: The Chinese translation of the US patent document and its

relevant parts with a publication date of March 14, 2000 and publication number

US6036127A;

Evidence 14: The publication date is April 11, 1975, the publication number

is SU459253, and the Chinese translation of the relevant part of the patent

documents of the former Soviet Union.

Among the above evidences, evidences 12 and 14 correspond to evidences 2 and

1 in the first invalidation, respectively.

(1) Take evidence 12 as the closest prior art

The petitioner believes that: with respect to Evidence 12, or Evidence 12

combines a limited number of derivations or experiments, or Evidence 12 combines

common knowledge or commonly used technical means in the field, or Evidence 12

combines any of Evidence 1, 6-10, and Evidence 4 , 5 or 14, claim 1 does not

possess an inventive step.

Evidence 12 discloses a number of technical solutions, wherein there are

stepped wave crests in the large corrugated lining plate composed of square

steel, and the crest is composed of at least two steps. Compared with this

technical solution, the technology of claim 1 and Evidence 12 The differences

between the schemes are: (1) the heights of the steps are all larger than the

radius of the small-diameter grinding ball and smaller than the radius of the

large-diameter grinding ball, and (2) the width of the steps is larger than the

radius of the small-diameter grinding ball.

Evidence 12 also discloses that steel balls of different diameters are used,

and the distribution law of the ball layer in the mill is that the small steel

balls are outside and the large steel balls are inside, that is, close to the

center of the mill; In the technical solution, it can be understood from the

context that d in the formula for calculating the width and height of the ridge

top of the ridge lining disclosed in evidence 12 refers to the average spherical

diameter, which can be obtained from the formula described in evidence 12, where

when b =0.8d, h2=0.5d, the height and width of the obtained rib conform to the

dimensional relationship restrictions on the height and width of the step in the

above differences (1), (2), but the above differences (1), (2) The mentioned

steps refer to at least two steps that form a wave crest, while the wave crest

is formed by only one ridge in evidence 12. Although evidence 12 discloses the

different technical features in claim 1 for different types of lining plates,

the technical solution using the rib lining plate in evidence 12 does not have

at least two steps, and the rib consists of a single step. The determination of

the top width and height of the rib is based on the consideration of whether it

can well constrain the ball layer resting on the liner and generate a moderate

lift, and does not involve the difference between grinding balls of different

diameters and two or more steps. The technical content of the matching work, and

the structure and shape of the convex rib lining plate and the large wave lining

plate composed of square steel are quite different, and the working mechanisms

of different types of lining plates are different. The formulas for the width

and height of the ridge top are directly used to determine the top width and

height of each step in the large corrugated lining plate composed of square

steel. Evidence 12 also cannot prove that the above distinction is adopted in

the case where the wave crest is formed by at least two steps. (1) and (2) are

common knowledge in the art to reduce the peak wear. Moreover, the petitioner

did not provide sufficient reasons or provide corresponding evidence to show

that obtaining the above distinctions (1) and (2) on the basis of evidence 12 is

a conventional technical choice in the art. Therefore, those skilled in the art

cannot obviously obtain the technical solution of claim 1 on the basis of the

different technical solutions disclosed in evidence 12 in combination with

common knowledge or conventional technical means in the art.

The liner in Evidence 4 has only one waveform, and the height of the waveform

is greater than the radius of the largest diameter grinding ball, which can

constrain balls of all diameters on the liner, and does not involve the mating

between balls of different diameters and more than two steps Work; The liner

installed in the cylinder in Evidence 5 has only one step, and does not disclose

the relationship between the height of the groove and the radius of the small

diameter grinding ball, nor does it involve the difference between balls of

different diameters and more than two steps Evidence 4 and 5 do not involve wave

crests formed by more than two steps, and do not disclose the restrictions on

the relationship between step height, width and ball diameter in the above

distinctions (1) and (2), nor do they give the corresponding technical

inspiration. The wave crest of the ball mill liner in Evidence 14 is

step-shaped, and a wave crest is composed of at least two steps, and the width

of the step is greater than the radius of the small-diameter grinding ball;

however, it is clearly recorded in Evidence 14 that the height of the step is

larger than that of the large-diameter grinding ball. On this basis, those

skilled in the art have no motivation to change the step height to be smaller

than the radius of the large diameter grinding ball. Evidence 1, 6-7, 9-10 only

involve the use of large-diameter and small-diameter grinding balls, and do not

involve the structure of the lining plate. The alumina balls in evidence 8 are

part of the lining plate, not as grinding media, It is completely different from

the action and working mode of the ball used in the ball mill in this patent.

The above evidence does not disclose the above differences (1) and (2), nor does

it give corresponding technical inspiration; even if it is common knowledge in

the art to use balls of different diameters in the ball mill, on the basis of

evidence 12, combine one of the above evidences The technical solution of claim

1 cannot be obtained obviously by one or more of them.

(2) Take evidence 2, 3 or 13 as the closest prior art

The petitioner believes that: with respect to any of the evidences 2, 3 and

13, in combination with evidence 12, or in combination with evidence 12 and a

limited number of derivations or experiments, or in combination with evidence 12

and common knowledge or conventional technical means in the field, or in

combination with evidence 12 and Any one of evidences 1, 6-10, and any of

evidences 4, 5, and 14, claim 1 does not have an inventive step.

After analysis, it can be seen that evidences 2, 3, and 13 do not disclose

the technical feature in claim 1: "the height of the steps is greater than the

radius of the small-diameter grinding ball and smaller than the radius of the

large-diameter grinding ball; the width of the steps is greater than The radius

of the grinding ball with small diameter", that is, the difference (1), (2)

between claim 1 and the technical solution of the large wave liner composed of

square steel in evidence 12. Evidences 2, 3, and 13 also do not give any

enlightenment on using the above-mentioned distinguishing technical features to

solve related technical problems.

As mentioned above, it is not easy for those skilled in the art to use the

formulas for the top width and height of the ridges in Evidence 12 to directly

determine the top width and height of each step in the large corrugated lining

plate composed of square steel. Evidence 12 Nor can it be proved that the above

distinctions (1) and (2) are common knowledge in the art to use the above

distinctions (1) and (2) to reduce the wear of the crest when the crest is

formed by at least two steps, and the applicant has not provided sufficient

reasons or provided corresponding evidence to show that Obtaining the above

distinctions (1), (2) on the basis of evidence 12 is a routine technical choice

in the art. Evidences 4, 5, and 14 also do not disclose the above-mentioned

distinguishing technical features, nor do they give any enlightenment on using

the above-mentioned distinguishing technical features to solve related technical

problems. Evidence 1, 6-7, 9-10 only involve the use of large-diameter and

small-diameter grinding balls, and do not involve the structure of the lining

plate. The alumina balls in evidence 8 are part of the lining plate, not as

grinding media, It is completely different from the action and working mode of

the ball used in the ball mill in this patent. Those skilled in the art cannot

obviously obtain the technical solution of claim 1 based on evidence 2, 3 or 13

in combination with one or more of the above-mentioned evidences. According to

the description of the patent specification, the above differences (1) and (2)

can effectively reduce the wave crest wear of the liner of the patent, which

brings beneficial technical effects to the patent.

Therefore, the claimant's invalidation grounds for taking evidence 2, 3 or 13

as the closest prior art and destroying the inventive step of claim 1 in

combination with other evidence cannot be established.

(3) Take Evidence 14 as the closest prior art

The petitioner believes that: with respect to evidence 14, in combination

with evidence 12, or in combination with evidence 12 and a limited number of

derivations or experiments, or in combination with evidence 12 and common

knowledge or conventional technical means in the field, or in combination with

evidence 12 and evidence 1, 6-10. Any one and any one of evidences 4 and 5,

claim 1 does not have an inventive step.

In this regard, the collegiate panel believes that:

The difference between claim 1 and evidence 14 is that the heights of the

steps in claim 1 are all greater than the radius of the small-diameter grinding

balls and smaller than the radius of the large-diameter grinding balls, while

the heights of the steps in evidence 14 are all larger than the large-diameter

grinding balls The above technical feature is also the difference (1) between

the technical solution of claim 1 and the technical solution of the large

corrugated lining plate composed of square steel in evidence 12.

Similar to the comments and identification of the above-mentioned

distinguishing technical feature (1) when Evidence 12 is the closest prior art,

although Evidence 12 discloses the use of grinding balls of different diameters,

and the technical solution of using a rib liner is disclosed in Evidence 12. ,

there is a limitation in the calculation formula for the height of the rib that

conforms to the relationship between the height of the step and the diameter of

the sphere in the above difference (1), but there are no at least two steps in

the technical solution using the rib liner in Evidence 12, The structure and

shape of the rib lining plate and the lining plate of evidence 14 are quite

different, the working mechanism of different types of lining plates is

different, and the step height clearly defined in evidence 14 is obviously

different from the scope of claim 1, those skilled in the art There is no

incentive to change the height of each step in the backing plate of evidence 14

to the height of the rib in evidence 12. Evidence 12 also does not prove that it

is common knowledge in the art to use the above distinction (1) to reduce crest

wear in the case of at least two steps forming crests, and the petitioner has

not provided sufficient reasons or provided corresponding evidence to show that

in the evidence. Obtaining the above distinction (1) on the basis of 12 is a

conventional technical choice in the art. Evidences 4 and 5 do not involve wave

crests formed by at least two steps, and neither disclose the limitation on the

relationship between step height and ball diameter in the above-mentioned

distinguishing technical feature (1), nor give corresponding technical

inspiration. Evidence 1, 6-7, 9-10 relate only to the combined use of large and

small diameter grinding balls and to the structure of the liner, the alumina

balls in Evidence 8 are part of the liner, not as The grinding balls used in the

patented ball mills function and work in a completely different way. The

above-mentioned evidence does not disclose the above-mentioned distinguishing

technical feature (1), nor does it give any technical inspiration for using the

distinguishing technical feature (1) to solve related technical problems; Those

skilled in the art cannot obviously obtain the technical solution of claim 1

based on the content disclosed in evidence 14 in combination with one or more of

the above-mentioned evidences. In addition, there is currently no sufficient

reason or evidence to show that it is common knowledge or conventional technical

means in the art to use the steps described in the above distinction (1) to

cooperate with grinding balls of different diameters to reduce peak wear.

Therefore, a person skilled in the art cannot obviously obtain the technical

solution of claim 1 based on the various ways of using evidence 14 as the

closest prior art proposed by the applicant. Based on the above difference (1),

the lining plate of the present patent can effectively reduce the wear of the

wave crest of the lining plate, and has beneficial technical effects. The

claimant's use of evidence 14 as the evidence closest to the prior art cannot

deny the inventive step of claim 1.

Summarize

Although there is only one claim in this case and the length is very short,

it limits the structure of the ball mill liner with multiple numerical ranges,

"the height of the steps is greater than the radius of the small-diameter

grinding ball and smaller than the radius of the large-diameter grinding ball;

The width of the steps is larger than the radius of the small-diameter grinding

balls”, and the above limitation can just achieve the technical effect that the

small balls are placed on the steps of the lining plate, the large balls roll on

the small balls, and the damage to the raised parts of the steps can be avoided.

.

Through the analysis of the two invalid evidences, either the diameter of the

grinding ball is not clearly distinguished, or the step height is not clearly

defined, the technical solution in this patent is not directly given, and the

lining of the mill is forcibly put in one piece of evidence. The combination of

the plate and the grinding ball of the grinding machine in other evidences

cannot provide the technical effect in this patent without combining

enlightenment. Therefore, it is reasonable that a seemingly simple invalidation

case has no invalidation success. The technical solution of this case is simple,

but the retrieval is quite difficult. Interested readers can combine the

retrieval elements and try to retrieve one or two.